In industries where hazardous materials are handled, the role of robotics is becoming increasingly important. Robotics can assist in the safe handling of dangerous substances, minimizing the risk of exposure to human workers. From nuclear power plants to chemical manufacturing facilities, robots are being used to perform tasks that are too dangerous for humans.

One of the key benefits of using robotics in the handling of hazardous materials is the ability to access confined spaces or environments with high levels of contamination. Robots can be equipped with sensors and cameras to navigate these areas safely and efficiently, reducing the need for human workers to put themselves at risk.

Robots can also be used to perform repetitive or tedious tasks, such as moving materials from one location to another or conducting routine inspections. By automating these tasks, companies can improve efficiency and reduce the likelihood of accidents caused by human error.

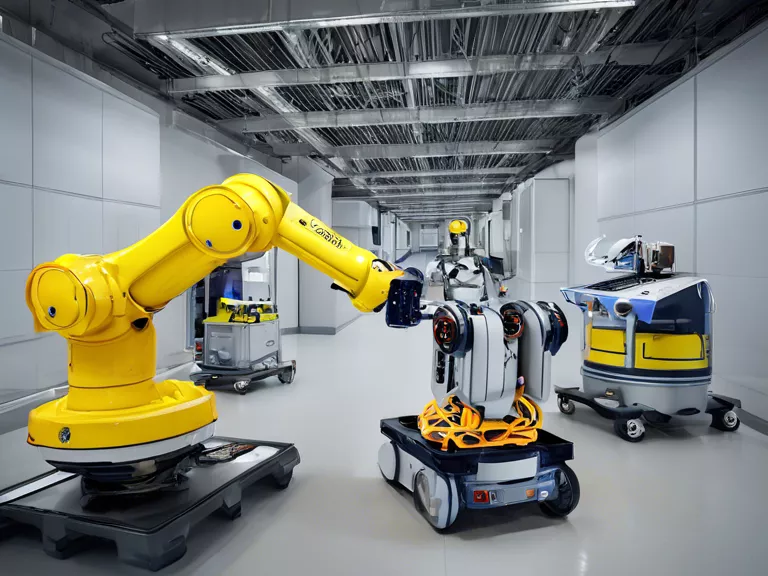

Furthermore, robots can be used to handle materials that are sensitive to contamination or require precise handling. By using robotic arms or grippers, companies can ensure that materials are handled with care and precision, reducing the risk of spills or leaks.

Overall, the role of robotics in assisting with hazardous material handling is crucial for ensuring the safety of workers and the protection of the environment. As technology continues to advance, we can expect to see even more innovative robotic solutions for managing hazardous materials in a variety of industries.